-

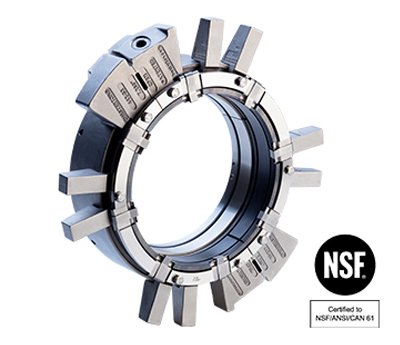

Chesterton 442C XL Cartridge Split Mechanical Seal

Equipment disassembly leads to high maintenance and operating costs as well as safety risks, but with extremely large pumps and other rotating equipment the stakes are even higher. The Chesterton 442C XL Split Seal, which suits equipment shafts from 5.00″ (125 mm) upto 7.75″ (195 mm), allows for seal installation without disassembly of large pumps, helping customers avoid extended downtime, lifting of heavy components, and disruption to nearby equipment.

The XL also has the following features that simplify reliable installation and operation:

- Spring Carrier Plate: Reduces installation errors and saves time

- Unique O-Ring Grooves: Greater sealing capability for use in more applications

- Automatic Self-Aligning Faces: Aligned and compressed automatically without manual handling

- Interlocking Rotary Face: Positively locates the face halves for greater sealing reliability

Features:

- Simple cartridge installation—without equipment disassembly

- Innovative design with superior performance

- Fits the majority of rotating equipment

- Easy field repair

- Certified to NSF/ANSI 61

-

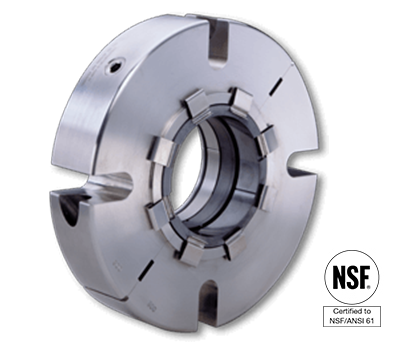

Chesterton 442M Mixer Split Seal

Split Seal that Accommodates Radial and Axial Shaft Motion for Industrial Mixers & Agitators

The Chesterton 442M split mechanical seal eliminates the need for equipment disassembly during seal installation and reduces maintenance costs. This split technology includes vacuum-to-positive pressure capability, which is especially beneficial in process vessel material transfer. It accommodates large radial and axial shaft motion associated with industrial mixers, agitators, reactors, and blenders.

- Installation is made easy with patented, automatic centering

- Uses many patented features allowing for easy and cost-effective field repair

- The unique ball-and-socket O-Rings are the easiest to install and are leak-free without the use of adhesives

- Available in sizes ranging from 20 mm to 610 mm (.75″ in.-24 in.)

Features:

- Ball-and-socket O-rings

- Patented, automatic centering

- Patented, captive fasteners that will not fall out

- Large axial and radial motion handling capability

- Full vacuum and high pressure sealings

- Non-clog external springs

- Non-fretting to equipment

- Dry run capable

- Compact design

- Integral dual flushport

-

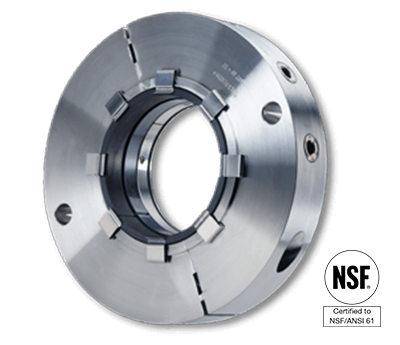

Chesterton 442PR Split Seal with Pumping Ring

The design of the Chesterton 442PR split seal is ideal for hot heater drains and boiler feed pumps where cooling to a single seal must be provided.

The high capacity pumping ring provides for maximum heat removal and reliability in hot water services. The 442PR delivers the lowest cost of ownership from its ease of installation, low cooling, and reliability.

Features:

- High-flow pumping device

- Designed for API Plan 23

- Engineered for high pressure

- High strength external springs

- Non-fretting to equipment

- Premium, high-graphite carbon face

- Ball-and-socket O-Rings

- Patented, automatic centering

- Certified to NSF / ANSI 61

-

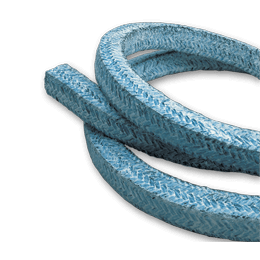

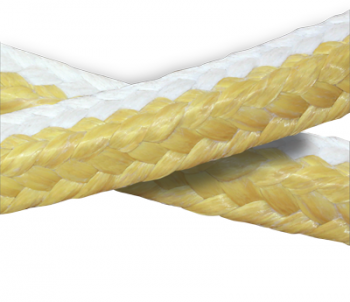

Chesterton 477-1 Carbon Fiber Packing

Chesterton 477-1 carbon fiber packing combines a new yarn formulation with superior blocking agents. New, low modulus yarn provides the strength associated with continuous filament carbon fibers plus greater flexibility. This makes 477-1 strong, yet pliable, without the brittleness of conventional carbon packing.

Chesterton 477-1 incorporates a high-purity dispersion of inorganic platelets which prevent penetration of gases or liquids through the packing. Inter-braid construction locks these blocking agents within the packing ring.

Features & Benefits

- Strong, yet pliable, staple carbon yarn

- Unique inorganic blocking agent stops gas/liquid penetration

- Molybdenum-based corrosion inhibitor prevents stem pitting

-

Chesterton 477-1T Carbon/PTFE Packing

Chesterton 477-1T is a tough, yet pliable, continuous filament carbon yarn packing impregnated throughout with PTFE to provide a non-contaminating, non-staining carbon yarn packing. Developed for the tough applications in the pulp and paper industry, 477-1T is specially designed to be used in high pressure feeders, pre-steaming vessels and applications that are moving abrasive slurries. This packing’s combined force of carbon yarn and PTFE dispersions increases its chemical resistance against strong caustic and acid mediums.

Chesterton 477-1T is also an excellent bottom anti-extrusion end ring when coupled with Chesterton 1400R Carbon-Reinforced Graphite Packing in rotating equipment. This combination is ideal for reducing or eliminating flush water from a stuffing box.Features & Benefits- Non-contaminating, non-staining carbon yarn packing

Unique inorganic blocking agent stops gas/ liquid penetration - Molybdenum-based corrosion inhibitor prevents stem pitting

- Non-contaminating, non-staining carbon yarn packing

-

Chesterton DualPac® 2212 Packing

A reliable sealing solution can save you both time and money on your pump operation. Traditional braided pump packing requires frequent gland adjustments and often burns out quickly, especially under high speeds. This results in packing failure and equipment damage.

Chesterton® DualPac 2212 is created using our patented DualPac Technology, which combines a burn-resistant material on the packing’s shaft side with a highly resilient outer fiber. This formulation creates a unique, long-lasting packing that uses the gland load more efficiently and achieves a reliable and quicker break-in period. This ability keeps the packing internally loaded against the rotating member while, at the same time, resisting burning and shaft scoring. DualPac 2212 gives users peace of mind in the toughest sealing applications.

DualPac Technology Advantages

- Significantly fewer gland adjustments than traditional packing

- Simplifies your inventory: you can use the same packing for end rings and sealing rings

- Better utilization of gland load in sealing configuration

- Minimizes shaft scoring

- Requires less overall maintenance

-

Chesterton GraphMax Packing

Chesterton GraphMax is an inter braided graphite packing. Carbon yarns are incorporated in the braided structure in a way that allows very tight braiding and corner reinforcement that improves the strength of the packing. This dramatically improves the packing’s resistance to extrusion and blow out, one of the limitations of traditional, flexible, graphite tape packings.

GraphMax can be used in demanding rotating applications such as those in the power, pulp and paper, and ore processing industries where temperature and pressure resistance can be required in combination with chemical and abrasion resistance.

GraphMax’s applicability in valves makes it a convenient plant-wide general service packing.

Features & Benefits

- Exclusive construction for plant-wide use in pumps and valves

- Maintains structural integrity for easy removal

- Carbon fiber-reinforced graphite strands provide maximum extrusion resistance and high-pressure capability

-

Chesterton NSF 61 Seals

Chesterton Expands NSF 61 Certification to All Single Cartridge and Split Mechanical Seals

To meet the growing demand for certified drinking water supplies, Chesterton has expanded its offering of NSF 61 certified mechanical seals to include all its single cartridge seals as well as split seals.

Developed by a team of scientists, industry experts and key industry stakeholders, NSF/ANSI/CAN 61 sets health effects criteria for many water system components. The majority of water treatment or distribution products in North America are now required to comply with NSF/ANSI/CAN 61: Drinking Water System Components – Health Effects by governmental agencies that regulate drinking water supplies.

Previously, Chesterton’s NSF products were limited to the 155 Single Cartridge Seal and the Chesterton 442 with RSC faces. The company recently received approval for ALL Chesterton single cartridge seals as well as its flagship Chesterton 442 and 442C split seals.

The certifiable seal configurations are as follows:

- 155, 150, S10 (Seal Faces: CB/SSC EP, SSC/SSC EP) including variants

- 442C, 442 (Seal Faces: CB/RSC EP, RSC/RSC/EP) including variants

Chesterton also offers an industrial coating NSF 61 certified product, ARC S1PW, which protects pipes and other structures against erosion, corrosion, and chemical attack.

-

Chesterton S10 & S20 Cassette Type Cartridge Seal

These high-performance mechanical seals have a unique modular cassette design that combines advanced seal technology with flexibility in maintenance and repair. Repair becomes a matter of simply exchanging cassettes, making it faster and easier, while significantly reducing costs.

A cassette seal offers a unique module design that combines high performance seal technology with flexibility in maintenance and repair. Repair becomes a matter of simply exchanging cassettes, making it faster and easier, while significantly reducing costs.

Common sizes currently in stock at Powerflo Products Inc. Chesterton S10 Cartridge seals in stock to fit many pumps such as these ANSI pump brands/models: Griswold 811, Summit 2196, Peerless 8196, Goulds 3196, Durco mark III, Summit Clark 3, Aurora 3550. Ahlstrom CPT, Sulzer CPT.

Powerflo is an authorized Chesterton Mechanical Seal Distributor in California.

-

Chesterton SuperSet Total Sealing Solution Featuring SpiralTrac

The Chesterton SuperSet™ combines the superior sealing capabilities of Chesterton’s compression packing products with the patented design of the EnviroSeal SpiralTrac™ Version P Environmental Controller for packed stuffing boxes. This total sealing solution set is proven to increase packing and equipment service life while dramatically reducing flush rates.

The SpiralTrac Version P actually enhances the utilization of the flow and centrifugal effects around the shaft; it performs similarly to a centrifugal separator.

- The built-in tangential lantern ring and helical grooving system impart motion to the flush, and the resulting centrifugal force throws the particulates in the fluid to the outside of the bushing.

- The patented SpiralTrac grooving system then hydro-dynamically pumps the solids to the bottom of the stuffing box and back out into the pump casing.

- The ability to remove particulate from the stuffing box is what differentiates the SpiralTrac from plain restriction bushings on the market today.

Chesterton offers six high-performance compression packing options in the SuperSet that cover a complete range of applications while meeting the needs and requirements of various industries

Features & Benefits- Reduces flush water consumption

- Increases equipment MTBR; extends packing life 2 to 6 times of traditional packing

- Reduces shaft sleeve wear

- Reduces number of packing rings

800-758-4788 |CONTACT US

Products

© Copyright 2016. All Rights Reserved.