-

Chesterton 180 & 280 Heavy-Duty Cartridge Seal

Chesterton 180 Heavy-Duty Cartridge Single SealGreater Sealing Reliability for a Wide Range of ApplicationsA heavy-duty single cartridge seal specifically designed for maximum reliability in demanding applications. The full-featured gland provides quench and drain capability. Designed to fit ANSI pumps with no modifications for ease of use.

Features:- Maximum performance for demanding, high-torque applications

- Reliable sealing of slurries

- Certified to NSF/ANSI 61

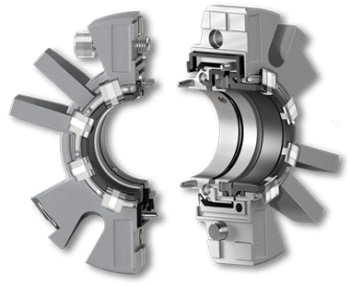

Chesterton 280 Cartridge Double Mechanical SealHeavy Duty Capabilities for Difficult ApplicationsThis double mechanical seal allows for a new, higher level of reliability and performance with the convenience of a cartridge seal. The Chesterton 280™ Double Mechanical Seal is specifically designed to handle demanding, high-torque applications.

This product is an ideal selection for such difficult applications as high concentration black liquor, hard-to-seal monomers such as acrylonitrile, vinyl chloride monomer, and any other potentially viscous solidifying liquids.

Features:

- High-reliability sealing

- Maximum solids handling capability

- Superior performance for demanding applications

- Motion tolerant for mixer applications

-

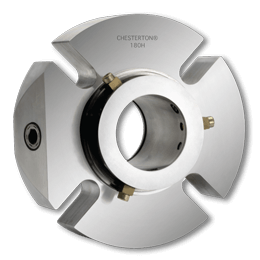

Chesterton 180H Single Cartridge Seal

An exceptional high temperature seal, the Chesterton180H Single Cartridge Seal uses an advanced hydropad geometry seal face that improves film formation between the mechanical seal faces and significantly enhances face lubricity. The increased film formation between the faces reduces heat generation and increases seal life in many high temperature applications.

Hydropad designs are useful in high-pressure applications—where pressure has a tendency to distort the seal faces and where the face velocity increases heat generation and in sealing fluids that have poor lubrication properties. Hot water applications are a prime area where hydropad technology can be utilized to improve sealing reliability. The 180H seals water at high temperature without environmental controls to temperatures up to 260°C (500°F).

Features:

- A high temperature seal also designed for high speed and pressure

- External cooling requirements are not needed for most applications, eliminating support equipment

- Advanced hydropad geometry minimizes seal facewear and distortion

- Reduces the frictional seal face heat concerns common with standard contacting seal face designs

- Hydropad geometry increases pressure velocity parameters over standard seal face designs

- Compact cartridge design for easy and reliable installation

- Use where external cooling is intermittent, limited, or unavailable

-

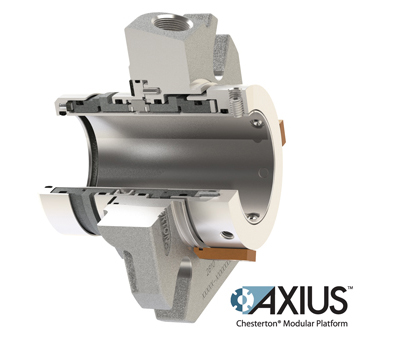

Chesterton 1810 & 2810 Heavy-Duty Modular Cartridge Seals

1810 Heavy-Duty Modular Single Cartridge SealThis Chesterton® single cartridge seal offers you the ultimate in seal quality, flexibility, and emissions control.

Leveraging Chesterton’s proprietary AXIUS modular platform, the 1810 can be configured with several different face profiles and auxiliary components within a common gland housing. This flexibility allows seal performance to be tailored to a wide range of process conditions.

A plant-wide sealing solution, the 2810 uses a geometric double-balanced seal face design. An optimized barrier/buffer channel for enhanced fluid flow provides greater seal reliability even at elevated temperatures.

2810 Heavy-Duty Modular Double Cartridge Seal

This Chesterton® double cartridge seal offers you the ultimate in seal quality, flexibility, and emissions control.

Leveraging Chesterton’s proprietary AXIUS modular platform, the 2810 can be configured with several different face profiles and auxiliary components within a common gland housing. This flexibility allows seal performance to be tailored to a wide range of process conditions.

A plant-wide sealing solution, the 2810 uses a geometric double-balanced seal face design. An optimized barrier/buffer channel for enhanced fluid flow provides greater seal reliability even at elevated temperatures.

-

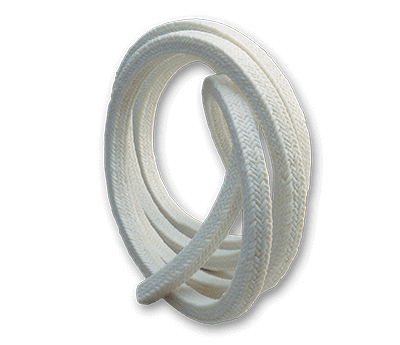

Chesterton 1830 Graphite PTFE Packing

Chesterton 1830 is an advanced, expanded, graphite PTFE packing made up of filaments developed to meet rigid specifications. It is well-suited for use in pumps, valves, agitators, mixers, and other rotating equipment. The PTFE resin is combined with graphite and expanded by using the latest technologies, resulting in a high-quality filament.

Features & Benefits

- Excellent chemical resistance

- Low friction, less heat generation, and non-abrasiveness saves shafts and shaft sleeves

- Easy installation and removal

- Low leakage and long life

-

Chesterton 1830 SSP Slurry Pump Packing

Chesterton 1830SSP Slurry Pump Packing is manufactured with a hybrid yarn, combining advanced, expanded, graphite PTFE yarn with carbon yarn reinforcement. This unique construction of yarns yields a packing that is easily removable during repack, resulting in reduced downtime. 1830SSP can be used in a wide range of slurry sealing applications, from a submersible slurry pump to a mining slurry pump.

1830 SSP Slurry Pump Packing Features & Benefits:

- Developed to meet rigid demands of slurry sealing application

- Excellent chemical resistance

- Low friction, less heat generation, non-abrasive; saves shafts and shaft sleeves

-

Chesterton 329 Stern-Lon Marine Flax Shaft Packing

Chesterton 329 Stern-Lon® is square-plait-braided to provide an unusually flexible, formable shaft packing. The base fiber is a long-fibered, roved flax of the highest quality. 329 is graphite-free to avoid galvanic corrosion on shafts.

During production, 329 is first impregnated with concentrated PTFE dispersion to promote non-flowing lubricity and to retard degradation. This is followed with a plasticizing “break-in” lubricant which assures compressibility, flexibility, and good packing-to-shaft contact. Large sizes need not be hammered into place. Finally, to minimize frictional attrition, a finely divided fluorocarbon powder is embedded into the surface of the packing. Chesterton 329 produces little or no shaft or sleeve wear.

Features & Benefits- Suitable for stern tube and paper mill packing

- Most recognized product for the marine industry in Stern tubes

-

Chesterton 370 Heat-Dissipating Packing

Chesterton 370 Heat-Dissipating Packing is a unique, carbon and graphite construction packing provides plant-wide utility off a single spool. Chesterton 370 is manufactured from a high-quality carbon yarn incorporated with particles of pure graphite, high-temperature tolerant oils, and molybdenum disulfide, all of which act as long-life lubricants and blocking agents. The low-friction carbon yarn has exceptional high-temperature capability in a non-oxidizing environment. *

Features & Benefits- Design for high-temp seal conditions

- Fast break-in

- Controls leakage with minimal friction

- Reduced leakage and flushing

-

Chesterton 377 CarbMax Packing

Chesterton 377 CarbMax™ packing combines one of the highest carbon content fiber yarns using the latest formulations with the newest blocking agents. This yarn provides the enhanced strength and toughness of a continuous multi-filament carbon fiber with additional increased durability. This makes the 377 firm, yet resilient, with high thermal conductivity over the conventional carbon packing.

Chesterton 377 incorporates a special formulated inorganic dispersion applied throughout the packing braid which prevents penetration and migration of gases or liquids. The inter-braid construction provides superior interlocking between all the strands of yarn with the additional blocking agents added to the composition of this unique mechanical packing.

Features & Benefits- Dense, yet resilient, continuous multi-filament carbon yarn

- Latest formulation & construction combined with newest blocking agents

- High thermal conductivity for maximum heat dissipation

-

Chesterton 412-W Synthetic Multi-Service Packing

Chesterton 412-W combines a newly developed synthetic composite yarn with a specially formulated break-in lubricant. Continuous filament center provides 10 times the tensile strength of typical packing fibers.

- Fibrous covering enables 412-W to absorb twice the PTFE blocking agents of conventional packing

- Chesterton interbraid construction helps prevent migration of blocking agents so that 412-W maintains density to prevent wicking throughout its service life

- Incorporates a purified colloidal lubricant to prevent failure at start-up and maintain continuous lubrication throughout the break-in process

412-W Synthetic Multi- Service Packing Technology Advantages:

- Pure white packing

- Superior tensile strength

- Holds twice the PTFE blocking agent of traditional fibers

-

Chesterton 425 Food Process Packing

Chesterton 425 is manufactured with a virgin PTFE filament and a white oil lubricant. It is perfectly suited for use in valves and also in rotating equipment such as blenders, mixers, agitators and other rotating equipment. Chesterton 425 complies with the USDA requirements for minimal food contact and FDA specification 21 CFR, 178.3620 for lubricants with incidental food contact as well as 177.1550 perfluorocarbon resins.

Features & Benefits- Meets USDA requirements

- Meets FDA requirements 21 CFr 178.3620(a) and 21 CFr 177.1550

- For use in valves, pumps, and other rotating and reciprocating equipment

-

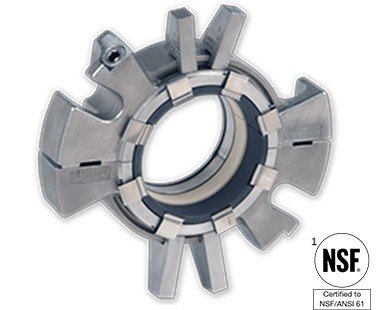

Chesterton 442 Split Seal

High-Performance Seals Available in Large DiametersThe Chesterton 442 split seal is ideal for equipment that is difficult and time-consuming to disassemble, such as large pumps, vertical pumps, and horizontal split case pumps. This proven, compact design can be used in a wide variety of equipment and process fluids.

The patented, high-performance split technology allows the 442 to operate from vacuum to high pressures.

- Compact design allows for easy installation and a fit advantage on most equipment

- Split, low-cost repair kits reduce ongoing maintenance costs even further

- Designed with the installer in mind, the ball-and-socket O-Rings provide a quick and easy leak-free seal without the use of adhesives

- Captive screws cannot fall out, making installation straightforward and reliable

1NSF version available upon request.

Features:

- Fully split mechanical seal

- Ball-and-socket O-Rings

- Adjustable gland tabs

- Patented, automatic centering

- Patented, full-vacuum capability

- Engineered for high pressure

- Non-clog external springs

- Non-fretting to equipment

- Dry run capable

- Large seal diameter options

- Integral dual flushport

- Certified to NSF/ANSI 61

-

Chesterton 442C Split Cartridge Seal

Chesterton is the world leader in design innovation of split seals. Our innovative split seals have been used to seal thousands of process-critical pieces of rotating equipment with exceptional results and many years of leak-free operations.

Chesterton was the first company to offer commercially-viable split seals for plant-wide use, which revolutionized pump sealing across industries. Since that time, we’ve launched a number of innovative split seal designs now used as a standard by companies around the globe. We offer shaft diameters ranging from 25-914 mm (1-36 in.)

Common sizes currently in stock at Powerflo Products Inc.

Powerflo is an authorized Chesterton Mechanical Seal Distributor in California.

800-758-4788 |CONTACT US

Products

© Copyright 2016. All Rights Reserved.