-

Chesterton 377 CarbMax Packing

Chesterton 377 CarbMax™ packing combines one of the highest carbon content fiber yarns using the latest formulations with the newest blocking agents. This yarn provides the enhanced strength and toughness of a continuous multi-filament carbon fiber with additional increased durability. This makes the 377 firm, yet resilient, with high thermal conductivity over the conventional carbon packing.

Chesterton 377 incorporates a special formulated inorganic dispersion applied throughout the packing braid which prevents penetration and migration of gases or liquids. The inter-braid construction provides superior interlocking between all the strands of yarn with the additional blocking agents added to the composition of this unique mechanical packing.

Features & Benefits- Dense, yet resilient, continuous multi-filament carbon yarn

- Latest formulation & construction combined with newest blocking agents

- High thermal conductivity for maximum heat dissipation

-

Chesterton 412-W Synthetic Multi-Service Packing

Chesterton 412-W combines a newly developed synthetic composite yarn with a specially formulated break-in lubricant. Continuous filament center provides 10 times the tensile strength of typical packing fibers.

- Fibrous covering enables 412-W to absorb twice the PTFE blocking agents of conventional packing

- Chesterton interbraid construction helps prevent migration of blocking agents so that 412-W maintains density to prevent wicking throughout its service life

- Incorporates a purified colloidal lubricant to prevent failure at start-up and maintain continuous lubrication throughout the break-in process

412-W Synthetic Multi- Service Packing Technology Advantages:

- Pure white packing

- Superior tensile strength

- Holds twice the PTFE blocking agent of traditional fibers

-

Chesterton 425 Food Process Packing

Chesterton 425 is manufactured with a virgin PTFE filament and a white oil lubricant. It is perfectly suited for use in valves and also in rotating equipment such as blenders, mixers, agitators and other rotating equipment. Chesterton 425 complies with the USDA requirements for minimal food contact and FDA specification 21 CFR, 178.3620 for lubricants with incidental food contact as well as 177.1550 perfluorocarbon resins.

Features & Benefits- Meets USDA requirements

- Meets FDA requirements 21 CFr 178.3620(a) and 21 CFr 177.1550

- For use in valves, pumps, and other rotating and reciprocating equipment

-

Chesterton 477-1 Carbon Fiber Packing

Chesterton 477-1 carbon fiber packing combines a new yarn formulation with superior blocking agents. New, low modulus yarn provides the strength associated with continuous filament carbon fibers plus greater flexibility. This makes 477-1 strong, yet pliable, without the brittleness of conventional carbon packing.

Chesterton 477-1 incorporates a high-purity dispersion of inorganic platelets which prevent penetration of gases or liquids through the packing. Inter-braid construction locks these blocking agents within the packing ring.

Features & Benefits

- Strong, yet pliable, staple carbon yarn

- Unique inorganic blocking agent stops gas/liquid penetration

- Molybdenum-based corrosion inhibitor prevents stem pitting

-

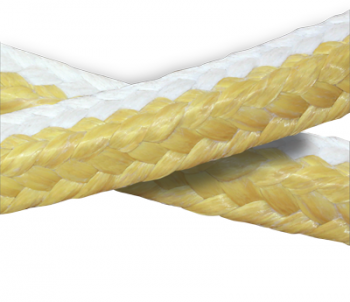

Chesterton 477-1T Carbon/PTFE Packing

Chesterton 477-1T is a tough, yet pliable, continuous filament carbon yarn packing impregnated throughout with PTFE to provide a non-contaminating, non-staining carbon yarn packing. Developed for the tough applications in the pulp and paper industry, 477-1T is specially designed to be used in high pressure feeders, pre-steaming vessels and applications that are moving abrasive slurries. This packing’s combined force of carbon yarn and PTFE dispersions increases its chemical resistance against strong caustic and acid mediums.

Chesterton 477-1T is also an excellent bottom anti-extrusion end ring when coupled with Chesterton 1400R Carbon-Reinforced Graphite Packing in rotating equipment. This combination is ideal for reducing or eliminating flush water from a stuffing box.Features & Benefits- Non-contaminating, non-staining carbon yarn packing

Unique inorganic blocking agent stops gas/ liquid penetration - Molybdenum-based corrosion inhibitor prevents stem pitting

- Non-contaminating, non-staining carbon yarn packing

-

Chesterton DualPac® 2212 Packing

A reliable sealing solution can save you both time and money on your pump operation. Traditional braided pump packing requires frequent gland adjustments and often burns out quickly, especially under high speeds. This results in packing failure and equipment damage.

Chesterton® DualPac 2212 is created using our patented DualPac Technology, which combines a burn-resistant material on the packing’s shaft side with a highly resilient outer fiber. This formulation creates a unique, long-lasting packing that uses the gland load more efficiently and achieves a reliable and quicker break-in period. This ability keeps the packing internally loaded against the rotating member while, at the same time, resisting burning and shaft scoring. DualPac 2212 gives users peace of mind in the toughest sealing applications.

DualPac Technology Advantages

- Significantly fewer gland adjustments than traditional packing

- Simplifies your inventory: you can use the same packing for end rings and sealing rings

- Better utilization of gland load in sealing configuration

- Minimizes shaft scoring

- Requires less overall maintenance

-

Chesterton GraphMax Packing

Chesterton GraphMax is an inter braided graphite packing. Carbon yarns are incorporated in the braided structure in a way that allows very tight braiding and corner reinforcement that improves the strength of the packing. This dramatically improves the packing’s resistance to extrusion and blow out, one of the limitations of traditional, flexible, graphite tape packings.

GraphMax can be used in demanding rotating applications such as those in the power, pulp and paper, and ore processing industries where temperature and pressure resistance can be required in combination with chemical and abrasion resistance.

GraphMax’s applicability in valves makes it a convenient plant-wide general service packing.

Features & Benefits

- Exclusive construction for plant-wide use in pumps and valves

- Maintains structural integrity for easy removal

- Carbon fiber-reinforced graphite strands provide maximum extrusion resistance and high-pressure capability

-

Chesterton SuperSet Total Sealing Solution Featuring SpiralTrac

The Chesterton SuperSet™ combines the superior sealing capabilities of Chesterton’s compression packing products with the patented design of the EnviroSeal SpiralTrac™ Version P Environmental Controller for packed stuffing boxes. This total sealing solution set is proven to increase packing and equipment service life while dramatically reducing flush rates.

The SpiralTrac Version P actually enhances the utilization of the flow and centrifugal effects around the shaft; it performs similarly to a centrifugal separator.

- The built-in tangential lantern ring and helical grooving system impart motion to the flush, and the resulting centrifugal force throws the particulates in the fluid to the outside of the bushing.

- The patented SpiralTrac grooving system then hydro-dynamically pumps the solids to the bottom of the stuffing box and back out into the pump casing.

- The ability to remove particulate from the stuffing box is what differentiates the SpiralTrac from plain restriction bushings on the market today.

Chesterton offers six high-performance compression packing options in the SuperSet that cover a complete range of applications while meeting the needs and requirements of various industries

Features & Benefits- Reduces flush water consumption

- Increases equipment MTBR; extends packing life 2 to 6 times of traditional packing

- Reduces shaft sleeve wear

- Reduces number of packing rings

800-758-4788 |CONTACT US

Packing

© Copyright 2016. All Rights Reserved.