-

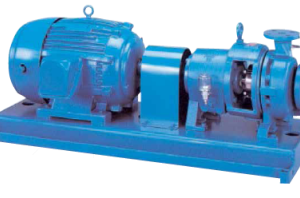

Aurora Pumps – 341A Close Coupled Centrifugal Pumps

Key Features

- End Suction Pumps are often used in general industrial water or clear fluid applications and also in offices and commercial buildings for internal Environment Control

- Computer-Machined Major Components with 360A Registered Fit

- Precision Cast, Dynamically Balanced, Enclosed Impeller Lasts Longer than the Competition

- Case Wearing Ring Prevents Wear on Casing and is Easily and Inexpensively Replaced

- Impeller Wear Rings are Also Available and Front Case Wearing Rings are Standard on All Models and Size Pumps

- Rear Support Foot provides Support and Simplifies Coupling Alignment

- Hydrostatic Tested Pump Casing Ensures Casting and Seal Integrity

- Applications Include:

- Chilled Water

- Heating and Air Conditioning

- Cooling Tower Makeup

- Water Booster System

-

Aurora Pumps – 344A Flexible Coupled Centrifugal Pumps

344A Aurora Pumps are available in various sizes and materials of construction as shown below:

- 344A-BF – Cast Iron Bronze Fitted

- 344A-AI – All Iron

- 344A-AB – All Bronze

-

Aurora Pumps – ANSI Regenerative Turbine Pumps

Powerflo Products Inc. designs and builds quality centrifugal ANSI pump and motor packages custom built and fabricated in our Cypress, California facility. Each unit is engineered for high reliability and efficiency while meeting your application’s pumping conditions and requirements.

-

Aurora Pumps California Distributor

Powerflo Products Inc. is a proud distributor of Aurora Pumps for California . Their line up of centrifugal pumps have served California with reliable and efficient pumping for decades. Many centrifugal pump designs are available including the following: ANSI, End Suction, Vertical Inline, Double Suction Split Case, Regenerative Turbine, Vertical Multi-Stage and Vertical Turbine.

Please contact our team at Powerflo for assistance with existing pumps and new application. As the authorized Aurora distributor and repair facility we can provide an efficient solution for your pump and process needs. We’re excited to help!

-

Baldor EL3504 Motor

Baldor Motor

Catalog # EL3504

Specs: .5HP,1745RPM,1PH,60HZ,56 Frame,TEFC

-

Baldor VEM3587T Motor

Baldor Motor

Catalog # VEM3587T

Specs: 2HP,1755RPM,3PH,60hz,145TC Frame, TEFC

-

Bear Cat Truck Pump

Roper Gear Pump Model for Asphalt Emulsion

These Roper Pumps are IN STOCK at Powerflo and ship same or next day for rapid delivery or pick up! No more pumps “made to order.” Keep your Bear Cat Truck in service now!

- Includes: 2-4″ NPT Flanged Ports, Teflon Packing, Bronze Bushings, Non-Jacketed, with Built In High PSI Relief Valve

- Heavy Duty Cast Iron Helical Gear Pump

- Speeds to 900 RPM, Flows to 468GPM

- Same dimensions as Bear Cat pumps

-

Burks DC-10 12V Washdown Pump

Burks DC-10 Wash Down Pump:

- 1 1/4″ Discharge X 1 1/2″ Inlet

- Heavy Duty Cast Iron Housing

- Noryl Impeller

- Flows to 20 GPM

- Up to 42 PSI

- 1HP, 12 Volt DC Motor

- Assembled and Pressure Tested at Powerflo Products Inc. in Cypress, CA, USA

Stainless Steel Option:

-

Burks DC-10 Wet End Kit

Burks DC-10 Wet End Kit:

- Complete pump sold less the motor

- Rebuild using your old motor

- Pump mounting fasteners included

-

Centrifugal ANSI Pump Packages

Powerflo Products Inc. designs and builds quality centrifugal ANSI pump and motor packages custom built and fabricated in our Cypress, California facility. Each unit is engineered for high reliability and efficiency while meeting your application’s pumping conditions and requirements.

Please contact us for pump packages to meet your existing or new application.

-

Chesterton 1400R Carbon-Reinforced Graphite Packing

Chesterton 1400R Carbon-Reinforced Graphite Packing:Reinforced, braided, graphite packing with a corrosion inhibitor. The carbon yarn reinforcement is provided within the graphite tape yarn as well as the braided construction.

- 1400R forms a homogeneous mass under gland pressure, so that leakage cannot penetrate the packing set.

- The all-carbon/graphite set withstands higher shaft speeds while limiting shaft friction.

- The structural carbon fiber reinforcement prevents extrusion when 1400R sets are installed in valves at higher pressures.

In addition to its excellent sealing capabilities in rotating equipment, 1400R is a superior valve sealing material. This dual purpose design makes it a truly universal mechanical packing.

Features & Benefits

- Passive molybdate-corrosion inhibitor

- Forms a homogeneous mass under gland pressure

- For use in valves and pumps

-

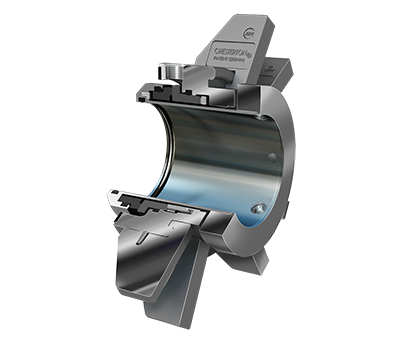

Chesterton 1510 General Duty Single Cartridge Seal

Simple Installation and Increased Reliability Plant-wide in General Duty Applications

Maximize maintenance efficiency and increase plant productivity with the 1510 Single Cartridge Seal. Designed to fit process equipment plant-wide by incorporating Chesterton T.A.B.S. (Tapered Adjustable Bolting System) the compact profile makes seal installation easy.

Reliability through temperature variations and intermittent operations is ensured with the use of monolithic seal faces and true non-fretting construction. Impeller adjustments after seal fitment are accommodated with the unique resettable centering strap, even when adjustment is required between routine maintenance. Incorporating Chesterton’s 5 key features of good mechanical seal design, the Chesterton 1510 sets the new standard for general duty cartridge seals.

Features:

- Reliable through temperature cycling and intermittent process with monolithic seal faces

- In service impeller adjustment is possible with the unique centering strap

- Mounts easily on various types of rotating equipment using Chesterton T.A.B.S.

- Prevents damage to your equipment and internal components via true non-fretting design

800-758-4788 |CONTACT US

Products

© Copyright 2016. All Rights Reserved.