-

Chesterton 1730 Mill Pack

Chesterton 1730 Mill Pack™ thermoset fiber packing provides outstanding heat resistance while maintaining excellent leakage control and reduced power consumption. Rugged, easy-to-use thermoset fiber packing controls leakage effectively while it is kind to shafts. 1730 Mill Pack provides high reliability in the most demanding applications. It is resistant to heat and will not glaze like common paper mill packing, even at high shaft speeds.

Mill Pack Features & benefits

- Easy and fast break in

- Abrasion resistant while non-scoring

- Strong chemical resistance

- Excellent heat resistance

-

Chesterton 1730SC Silicone Core Packing

Chesterton 1730SC packing combines a resilient silicone rubber core with the heat-resistant thermoset fiber of Chesterton’s MillPack 1730. The elastic, rubber core gives the packing better memory, allowing it to withstand radial shaft motion and vibration while maintaining excellent leakage control with minimal gland adjustments.

Rugged as well as easy to use and break in, 1730SC is designed for use in general service rotating equipment such as agitators, blenders, mixers, or any other applications that undergo shaft deflection in normal operating conditions.

Features & Benefits- Rugged, easy-to-use general service packing

- Withstands radial shaft motion and vibration

- Handles shaft / bore eccentricity

-

Chesterton 1740 Inter-Braid Packing

Chesterton 1740 is an inter-braided packing using aramid fibern with PTFE and other lubricants.* Each strand of yarn has been individually coated in order to dissipate heat. 1740 can be installed as full sets to offer combined resistance to pressure, temperature, chemicals, and wear. 1740 braided packing is also used as back-up rings for added extrusion resistance in abrasive applications.

Features & Benefits- Excellent extrusion resistance in abrasive applications

- Non-staining, non-contaminating

- Non-asbestos, multi-service packing

-

Chesterton 1760 Chemical Packing

Chesterton 1760 is a unique packing consisting of a PTFE yarn lubricated with graphite particles that dissipate heat. The finished packing is further lubricated with a special silicone oil for quick break-in.

1760 Chemical Packing Features & Technology:

- Excellent chemical resistance

-

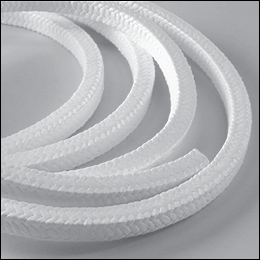

Chesterton 1765 White ePTFE Chemical Packing

Chesterton 1765 is ideally suited for bleach pumps and other rotary applications requiring a white, non-staining packing. Constructed from chemically resistant, expanded PTFE material, this packing demonstrates higher speed performance capabilities than traditional PTFE materials for improved performance in a wide range of applications. Chesterton 1765 is ideal for rotary applications where chemical resistance is required and process needs to remain non-contaminated, such as ClO2 pumps, paper stock, and feeders.

Features & Benefits- Non-staining

- Superior chemical resistance

- Low friction for improved speed capability

- Longer packing life

-

Chesterton 180 & 280 Heavy-Duty Cartridge Seal

Chesterton 180 Heavy-Duty Cartridge Single SealGreater Sealing Reliability for a Wide Range of ApplicationsA heavy-duty single cartridge seal specifically designed for maximum reliability in demanding applications. The full-featured gland provides quench and drain capability. Designed to fit ANSI pumps with no modifications for ease of use.

Features:- Maximum performance for demanding, high-torque applications

- Reliable sealing of slurries

- Certified to NSF/ANSI 61

Chesterton 280 Cartridge Double Mechanical SealHeavy Duty Capabilities for Difficult ApplicationsThis double mechanical seal allows for a new, higher level of reliability and performance with the convenience of a cartridge seal. The Chesterton 280™ Double Mechanical Seal is specifically designed to handle demanding, high-torque applications.

This product is an ideal selection for such difficult applications as high concentration black liquor, hard-to-seal monomers such as acrylonitrile, vinyl chloride monomer, and any other potentially viscous solidifying liquids.

Features:

- High-reliability sealing

- Maximum solids handling capability

- Superior performance for demanding applications

- Motion tolerant for mixer applications

-

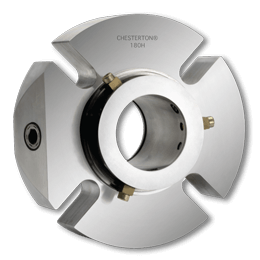

Chesterton 180H Single Cartridge Seal

An exceptional high temperature seal, the Chesterton180H Single Cartridge Seal uses an advanced hydropad geometry seal face that improves film formation between the mechanical seal faces and significantly enhances face lubricity. The increased film formation between the faces reduces heat generation and increases seal life in many high temperature applications.

Hydropad designs are useful in high-pressure applications—where pressure has a tendency to distort the seal faces and where the face velocity increases heat generation and in sealing fluids that have poor lubrication properties. Hot water applications are a prime area where hydropad technology can be utilized to improve sealing reliability. The 180H seals water at high temperature without environmental controls to temperatures up to 260°C (500°F).

Features:

- A high temperature seal also designed for high speed and pressure

- External cooling requirements are not needed for most applications, eliminating support equipment

- Advanced hydropad geometry minimizes seal facewear and distortion

- Reduces the frictional seal face heat concerns common with standard contacting seal face designs

- Hydropad geometry increases pressure velocity parameters over standard seal face designs

- Compact cartridge design for easy and reliable installation

- Use where external cooling is intermittent, limited, or unavailable

-

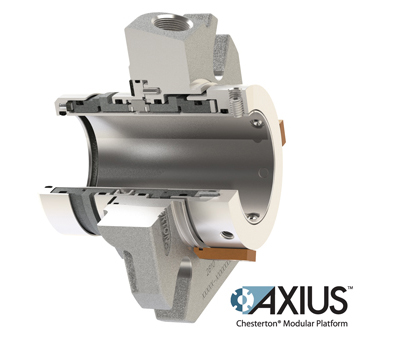

Chesterton 1810 & 2810 Heavy-Duty Modular Cartridge Seals

1810 Heavy-Duty Modular Single Cartridge SealThis Chesterton® single cartridge seal offers you the ultimate in seal quality, flexibility, and emissions control.

Leveraging Chesterton’s proprietary AXIUS modular platform, the 1810 can be configured with several different face profiles and auxiliary components within a common gland housing. This flexibility allows seal performance to be tailored to a wide range of process conditions.

A plant-wide sealing solution, the 2810 uses a geometric double-balanced seal face design. An optimized barrier/buffer channel for enhanced fluid flow provides greater seal reliability even at elevated temperatures.

2810 Heavy-Duty Modular Double Cartridge Seal

This Chesterton® double cartridge seal offers you the ultimate in seal quality, flexibility, and emissions control.

Leveraging Chesterton’s proprietary AXIUS modular platform, the 2810 can be configured with several different face profiles and auxiliary components within a common gland housing. This flexibility allows seal performance to be tailored to a wide range of process conditions.

A plant-wide sealing solution, the 2810 uses a geometric double-balanced seal face design. An optimized barrier/buffer channel for enhanced fluid flow provides greater seal reliability even at elevated temperatures.

-

Chesterton 1830 Graphite PTFE Packing

Chesterton 1830 is an advanced, expanded, graphite PTFE packing made up of filaments developed to meet rigid specifications. It is well-suited for use in pumps, valves, agitators, mixers, and other rotating equipment. The PTFE resin is combined with graphite and expanded by using the latest technologies, resulting in a high-quality filament.

Features & Benefits

- Excellent chemical resistance

- Low friction, less heat generation, and non-abrasiveness saves shafts and shaft sleeves

- Easy installation and removal

- Low leakage and long life

-

Chesterton 1830 SSP Slurry Pump Packing

Chesterton 1830SSP Slurry Pump Packing is manufactured with a hybrid yarn, combining advanced, expanded, graphite PTFE yarn with carbon yarn reinforcement. This unique construction of yarns yields a packing that is easily removable during repack, resulting in reduced downtime. 1830SSP can be used in a wide range of slurry sealing applications, from a submersible slurry pump to a mining slurry pump.

1830 SSP Slurry Pump Packing Features & Benefits:

- Developed to meet rigid demands of slurry sealing application

- Excellent chemical resistance

- Low friction, less heat generation, non-abrasive; saves shafts and shaft sleeves

-

Chesterton 329 Stern-Lon Marine Flax Shaft Packing

Chesterton 329 Stern-Lon® is square-plait-braided to provide an unusually flexible, formable shaft packing. The base fiber is a long-fibered, roved flax of the highest quality. 329 is graphite-free to avoid galvanic corrosion on shafts.

During production, 329 is first impregnated with concentrated PTFE dispersion to promote non-flowing lubricity and to retard degradation. This is followed with a plasticizing “break-in” lubricant which assures compressibility, flexibility, and good packing-to-shaft contact. Large sizes need not be hammered into place. Finally, to minimize frictional attrition, a finely divided fluorocarbon powder is embedded into the surface of the packing. Chesterton 329 produces little or no shaft or sleeve wear.

Features & Benefits- Suitable for stern tube and paper mill packing

- Most recognized product for the marine industry in Stern tubes

-

Chesterton 370 Heat-Dissipating Packing

Chesterton 370 Heat-Dissipating Packing is a unique, carbon and graphite construction packing provides plant-wide utility off a single spool. Chesterton 370 is manufactured from a high-quality carbon yarn incorporated with particles of pure graphite, high-temperature tolerant oils, and molybdenum disulfide, all of which act as long-life lubricants and blocking agents. The low-friction carbon yarn has exceptional high-temperature capability in a non-oxidizing environment. *

Features & Benefits- Design for high-temp seal conditions

- Fast break-in

- Controls leakage with minimal friction

- Reduced leakage and flushing

800-758-4788 |CONTACT US

Product Tag - RFQ Only

© Copyright 2016. All Rights Reserved.